В таких отраслях, как горнодобывающая промышленность, карьер, строительные материалы, и химическая обработка, эффективная проверка материала является важным шагом, который напрямую влияет на качество продукции., производственная мощность, и эксплуатационные расходы. Поскольку характеристики материалов становятся все более требовательными, особенно в отношении мелких и сверхмелких частиц, традиционные методы низкочастотного скрининга часто с трудом могут обеспечить стабильные и точные результаты..

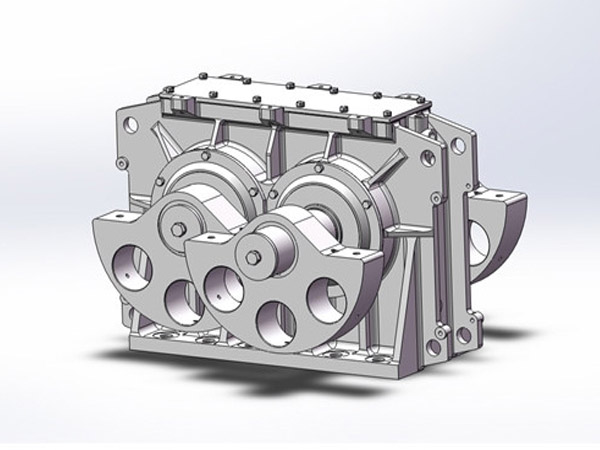

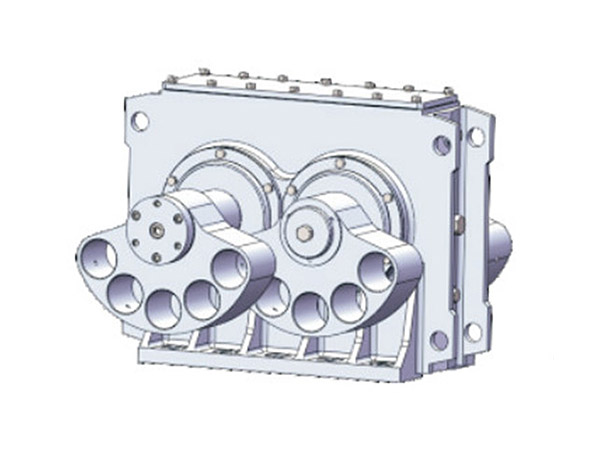

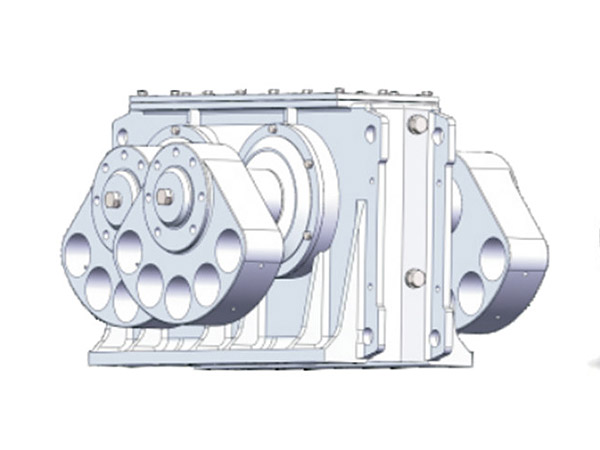

Вот где высокочастотный виброгрохот становится ключевым компонентом, повышающим производительность. Обеспечивая контролируемый, высокоскоростная вибрация, это значительно повышает точность скрининга, уменьшает время простоя, и повышает общую эффективность установки. Причины повреждения дорожек качения и профилактические меры, мы исследуем основные преимущества использования высокочастотного виброгрохота в современных промышленных приложениях..

Преимущества использования высокочастотного виброгрохота

1. Значительно улучшенная эффективность скрининга

Одним из наиболее заметных преимуществ высокочастотного вибросита является его способность значительно повышать эффективность просеивания.. Высокая частота вибрации создает интенсивное движение частиц по поверхности экрана., позволяя мелким материалам легче проходить через сетку.

По сравнению с обычными возбудителями, высокочастотные агрегаты особенно эффективны при обращении:

Мелкий песок и минеральные концентраты

Шламы и влажные материалы

Ультратонкие порошки, используемые в химической или промышленной обработке.

За счет ускорения разделения частиц, заводы могут достичь более высокой производительности без ущерба для точности, что приводит к более единообразной сортировке продукции и улучшению производительности последующей переработки..

2. Лучшее расслоение материала и уменьшение ослепления

Высокочастотная вибрация способствует эффективному расслоению материала.. Более мелкие частицы перемещаются вниз к отверстиям сита., в то время как более крупные частицы остаются на поверхности и движутся в сторону выброса. Этот непрерывный процесс разделения сводит к минимуму наслаивание материала и уменьшает распространенные проблемы, такие как засорение и засорение сит..

…

Более подробную информацию о преимуществах высокочастотных виброгрохотов при промышленном просеивании см., пожалуйста, нажмите, чтобы посетить:https://www.hsd-industry.com/news/benefits-of-using-a-high-frequency-vibrating-screen-exciter/