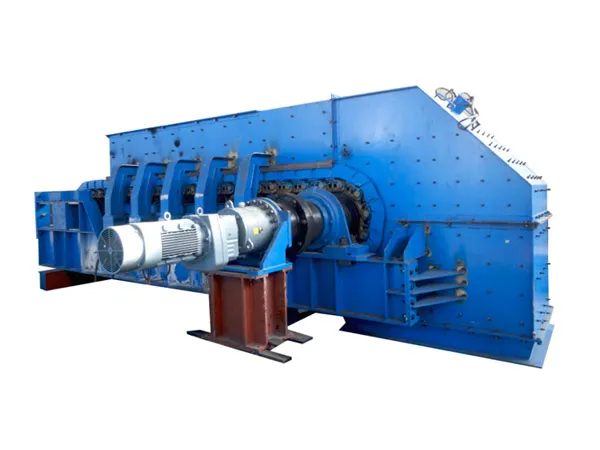

The materials are pressed into the pre- press device of the ball press with certain volume evenly when máquina de hacer briquetas de carbón laboral, and the stable material position shall be kept in the pre-press device.

The pre-pressing spring in the device will force the materials into the inter-space between the double rollers, then the materials shall be pre-pressed and transited to the arch groove of the pair-rollers.

The roller pits with the same shape are distributed evenly on the rollersurface. los 2 pair-rollers shall rotate at constant speed reversely through engagement drive.

The rollers will suck the materials at the entry into the groove and forcibly compress them.

With the continuous rotation of the pair-roller, the ball shall be taken off by the elastic force and gravity. The roller rotates to compress and form the materials periodically with the continuous operation of the motor to realize the batch production.

Briquetting is a process of compacting biomass, residuos agrícolas, or other materials into denser and more manageable forms called briquettes. These briquettes can be used as a source of fuel or for various industrial applications.

A comprehensive guide to briquetting solutions

1. Understanding Briquetting:

Definición: Briquetting involves compressing materials into compact, sólido, and uniform shapes.

materiales: Common materials include biomass, la madera, residuos agrícolas, la cal ha abierto una variedad de usos en muchos sectores industriales emergentes además del material principal de la ingeniería civil, and other organic materials.

Objetivo: Briquettes can be used for energy production, calefacción, and as a substitute for traditional fuels.

2. Briquetting Process:

Preparación: Collect and prepare raw materials. This may involve drying, shredding, and other pre-processing steps.

Alimentación: The prepared material is fed into the briquetting machine.

Compresión: Pressure is applied to the material to form briquettes. This is typically done using mechanical presses.

Binding Agents: En algunos casos, binding agents are added to improve the briquetting process and enhance the quality of the briquettes.

3. Tipos de máquinas briquetadoras:

Screw Extruder Press: Utilizes a screw to compact materials.

Prensa Mecánica: Employs a piston or die to apply pressure.

Prensa hidráulica: Uses hydraulic power for compression.

Roller Press: Utilizes two counter-rotating rollers to compact materials.

…

For more detailed information about comprehensive solutions for briquetting machines, por favor haga clic aquí: https://www.zymining.com/en/a/news/briquetting-solutions.html