The solid sand casting process has its unique advantages. There is no drafting angle and there is no model parting surface. It can not only save the cost of making wooden models for the production of single or small batches of machine bed, base and other castings. Moreover, it has the advantages of good surface quality, high dimensional accuracy and small processing allowance; it can also save the core making and drying process; it saves the cumbersome process such as the hanging core and the card core of the molding process, and the operation is more convenient; especially It shortens the production cycle and significantly improves the production efficiency, so it is favored by the machine tool casting industry.

1. Characteristics and problems of machine tool castings

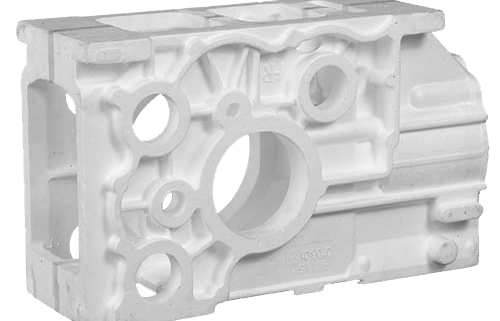

Large machine bed, column, base and box castings are usually made of HT200 ~ HT350. They generally have a complicated internal cavity structure, and the wall thickness is usually 12 ~ 30 mm. The traditional sand casting process (such as resin sand molding) requires more cores to form the inner cavity of the casting. There are some disadvantages:

(1) because the batch size of such castings is not too large, different model specifications require different wood molds. More cores require more core shell molds, which increases the cost and manufacturing cycle of the mold, and also increases the difficulty of mold management;

(2) Since the inner cavity is formed by combining a plurality of cores, the difficulty in controlling the dimensional accuracy of the casting is increased;

(3) The gap between the cores will enter the molten iron, forming flash edges and winged wings, and the grinding and cleaning work of the castings will increase the difficulty and difficulty.

In order to overcome the shortcomings of the above-mentioned traditional sand casting production, the resin sand foam solid casting process has been widely used in the production of large machine tool castings, but the foam solid casting also has some unfavorable characteristics, the most typical of which are three:

(1) Casting requires the formation of high-temperature molten iron to dissolve solid materials (such as EPS), which requires a large amount of heat, and therefore requires a higher pouring temperature;

(2) The pyrolysis material will generate a large amount of gas and residue, and the risk of forming pores and slag inclusions on the casting is high;

(3) A large amount of harmful gases containing benzene and toluene and black smoke are emitted during the pouring process, and environmental protection problems need to be solved. If the casting system is also made of a solid material such as EPS, the damage is even greater because the molten iron is first passed through the casting system.

The use of ceramic tube material as a casting system can effectively overcome the above shortcomings, but the ceramic tube casting system also has shortcomings:

(1) Ceramic tubes are hard, brittle, difficult to cut, and also heavy, and a slightly complicated casting system is difficult to assemble;

(2) The ceramic tube is sintered from the material of the sputum, and the pouring process is eroded by the erosion of the high-temperature molten iron, and there is a risk of falling into the cavity to form inclusion defects;

(3) The ceramic tube fragments after casting sand falling into the sand will be mixed into the sand recycling and regeneration system, which increases the difficulty and cost of recycling and recycling of the sand.

The use of paper materials instead of ceramic materials to make casting casting systems has many advantages and is a development trend. Firstly, the paper material is light and thin, easy to cut, and can be assembled into a complicated casting system. Secondly, the paper casting system is carbonized by high-temperature iron combustion, and the residual is small, and the risk of forming inclusion slag is extremely small; The mixing of ceramic runner tube residues into old sand creates problems that are difficult to clean and reclaim.

2. Application of paper sprue tube in solid casting of resin sand

The casting system of solid sand casting is the same as that of traditional sand casting. It consists of a pouring cup (gate basin), a sprue, a sprue, and a gate. The function of the molten iron is also fast. Smoothly attract people. For large and medium-sized machine tool castings, stepped or medium-sized injections are used to make the flow of molten iron as smooth as possible, and the filling is smooth and fast.

The number of sprues for medium and large machine tool castings can be set to two or more, and some large and extra large castings even need to place 4 to 6 sprues. A sprue basin shall be placed on the sprue to store a certain amount of molten iron. When the pouring is not interrupted, the molten iron can flow into the mold under normal pressure, which can effectively prevent back spray and bonfire from the sprue during pouring. .

The sprue uses a paper sprue tube and two or more sprues can use the same larger sprue basin. When using it, it should be noted that the paper sprue tube needs the sand type to provide support force, and the compactness of the molding sand should be suitable, but the sprue tube should not be damaged too much. The casting filling process is a high-temperature metal liquid casting cavity. The pouring pipe is subjected to the gravity flushing of the molten metal, and also has to withstand the tension of the high-temperature molten metal to the sprue pipe wall; the pouring system is in the high-temperature collecting zone, and all the entering the cavity The molten metal has to pass by. In particular, the use of large-tonnage castings requires that the outer wall of the “paper sprue tube” have a constant supporting force to ensure that the entire filling process is not destroyed.

The sprue and sprue tubes of the paper sprue tube can be connected as a whole, and the size and length of the caliber are determined by the casting system process of the casting. The connection method of the paper sprue tube is a socket interface, which is very convenient, and the length of the sprue tube can be cut by hand saw. The paper sprue tube and fittings are simple and flexible to assemble.

3. The link (assembly) method

(1) Socket (embedded). Insert the lower end of the hollow tube into the socket. It is best to apply a small amount of adhesive to the outer wall before insertion so that the connection between the two is better.

(2) Nesting (stop type). The bottom of the gate cup, the hollow tube of the paper sprue has an inner diameter of the outer diameter of the foam plastic white mold (which can be 0.5 mm larger, the foam plastic mold can be shrunk), and one end of the hollow tube is inserted into one end of the circular diameter of the foam plastic white mold ( Can not be painted in the nesting section).

(3) Bonding (section adhesive). When installing the paper sprue tube before the casting, in order to prevent the distortion and finally put it on the glass plate, according to the total amount of molten iron used in the casting + pouring system, including flow direction, flow selection sprue tube diameter, diameter reduction, turning, three The pipe, pipe and pipe used are all connected by sockets to ensure that the paper sprue pipe is firmly connected. In this way, it is possible to effectively prevent the occurrence of sand inclusion defects due to inadvertent operation during molding. If the two sections of the sprue of the paper sprue hollow tube are flat, the cross-section of the outer wall and the inner wall of the two-end tube and the cross section of the sprue must be adhered with adhesive glue, and wrapped with glass cloth or tape paper. can.

(4) Bonding plus refractory mud strips. The pouring cup and the hollow tube are not integrated, and the sprue is leaked out of the top surface of the sand box by 3~5 mm, and the hollow tube is tightly packed with a foam block to prevent debris. Place a circle of refractory mud strips around the box, place the sprue cups on top and join them with refractory mud strips at the joints (such as sealing mud strips), or the bottom surface of the sprue cups and the top surface of the sprue hollow tubes Adhesive with adhesive, the outer ring is brushed with refractory mud.

(5) Other bonding. According to the size and shape of the gate cup and the sprue, the hollow sprue can be modified according to the above method.