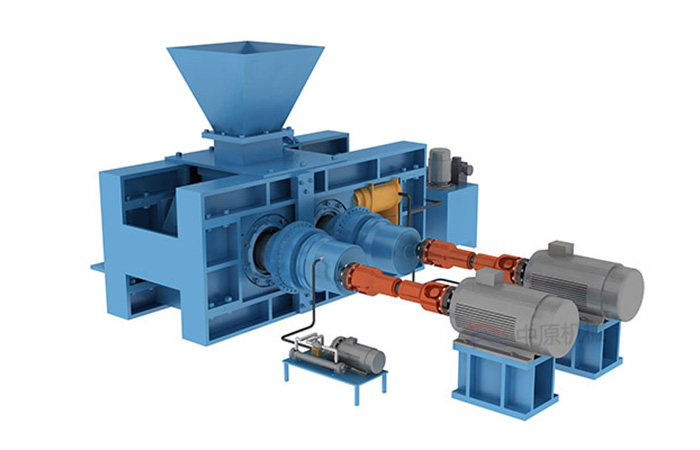

We all know that when some machinery and equipment need to generate excitation force, if the machine itself does not have this function, it needs to add some vibration devices. The vibrating screen needs to use mechanical vibration to screen materials. Therefore, vibration The screen exciter has become one of the important components of the vibrating screen.

When purchasing a vibrating screen exciter, many users generally focus on the quality and performance of the exciter. However, as long as the quality is passed, can the use of the vibrating screen exciter be completely assured? This is not the case. Although the quality of the exciter is the focus of attention, the use of the exciter is correct and reasonable, and it is also an important factor affecting the performance of the vibrating screen. If it is improperly operated for a long time, it is easy to cause the failure of the exciter, thus affecting the normal operation of the vibrating screen. As an old-fashioned vibrating screen exciter manufacturer, Luoyang Haiside Heavy Industry Co., Ltd. shares with you the precautions for the use of vibrating screen exciters, so that more people can learn the correct use of vibrating screen exciters.

The correct use of the vibrating screen exciter is summarized as follows:

1. Before starting the work, check the tightness of all the bolts, and after the initial work for 8 hours, check whether there is looseness and tighten again.

2. Check the oil level in the exciter. If the oil level is too high, the temperature of the exciter will rise or it will be difficult to operate. If the oil level is too low, it will lead to insufficient lubrication and damage to the bearing. Normally, 2/3 of the lubricating cavity should be filled. should.

3. Ensure a minimum clearance between all moving parts and fixed objects.

4. When the load of the vibrating screen starts, it will cause greater pressure on the bearing of the exciter and reduce the service life. Therefore, it is necessary to check the screen surface of the vibrating screen before opening to ensure that the vibrating screen is started under no load, and then start feeding after the vibrating screen runs smoothly. Before shutting down, the feeding should be stopped first, and the machine should be shut down after the material on the screen surface is drained.

Details can be accessed here:https://www.hsd-industry.com/news/the-use-of-vibrating-screen-exciter/