Aluminium sheet cladding has become a preferred choice for modern commercial and residential buildings. Its combination of lightweight strength, corrosion resistance, and aesthetic versatility makes it ideal for creating visually striking and long-lasting exterior walls. However, achieving the full benefits of aluminium cladding depends heavily on proper installation. This comprehensive guide provides practical steps, tips, and industry best practices to ensure a flawless facade that stands the test of time.

Aluminium Sheet Cladding Installation Guide for Exterior Walls

1. Planning and Material Selection

Proper planning is the foundation of a successful aluminium cladding project. Key considerations include:

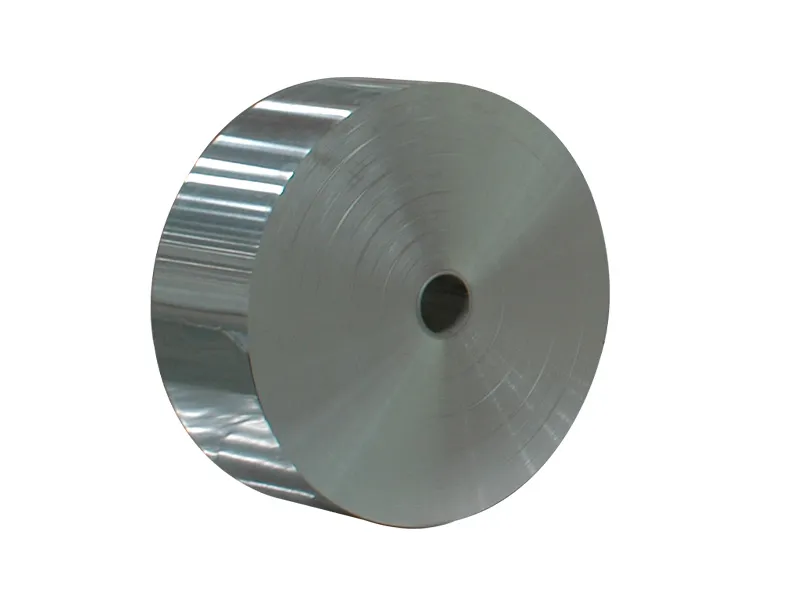

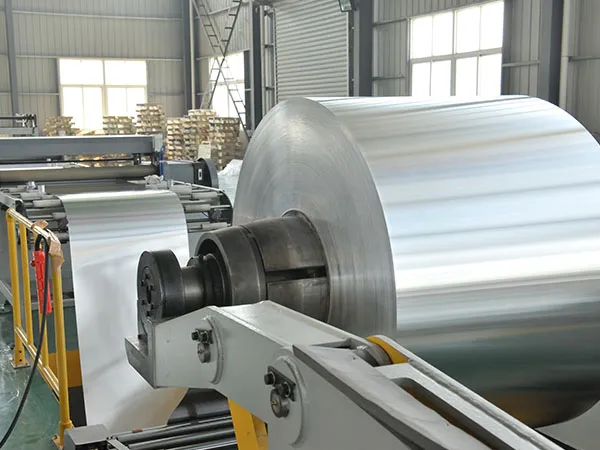

Type of Aluminium Sheets: Select from plain, perforated, or composite panels based on design, ventilation needs, and exposure to weather. Composite panels can offer additional insulation properties.

Thickness and Finish: For exterior walls, panels typically range from 2mm to 4mm. Powder-coated or anodized finishes improve durability and maintain color consistency over time.

Support Structure: Ensure the subframe (aluminium or stainless steel) can bear the panel weight, accommodate wind loads, and resist corrosion.

Investing time in planning reduces costly adjustments later and ensures structural stability for decades.

2. Preparing the Wall Surface

A well-prepared wall surface ensures secure attachment and alignment:

Cleaning: Remove dust, debris, grease, or moisture to prevent adhesion issues.

Leveling: Correct uneven surfaces with plaster or leveling compounds to avoid warping or gaps.

…

For more detailed information on aluminum panel exterior wall installation, please click to visit: https://www.dw-al.com/a/news/aluminium-sheet-cladding-installation-for-exterior-walls.html