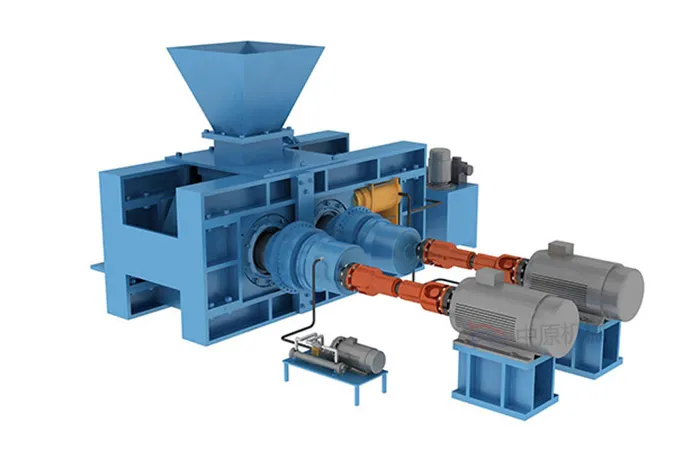

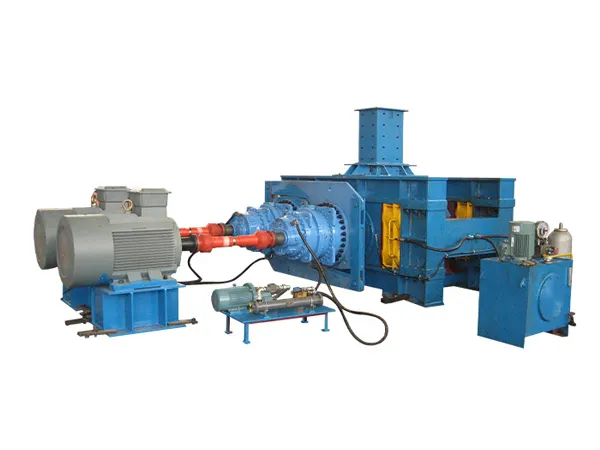

Шлифовальные валки высокого давления (HPGR), Оборудование для шлифования основного шлифования в таких отраслях, как цемент, добыча, и металлургия, являются критическими компонентами, которые оказывают огромное давление. Однако, под долгосрочным, Операция высокой нагрузки, Износ поверхности ролика HPGR - неизбежная проблема. Носит не только снижает эффективность производства и увеличивает потребление энергии, но также может вызвать простоя и значительные экономические потери. Эффективный и экономически эффективный ремонт поверхности ролика стал ключевой проблемой в отрасли.

Эта статья содержит углубленный анализ технологий восстановления роликовых поверхностей HPGR, Помогая вам выбрать наиболее подходящее решение для продления срока службы оборудования и повышения эффективности производства.

Понимание износа поверхности ролика: Почему ремонт необходим?

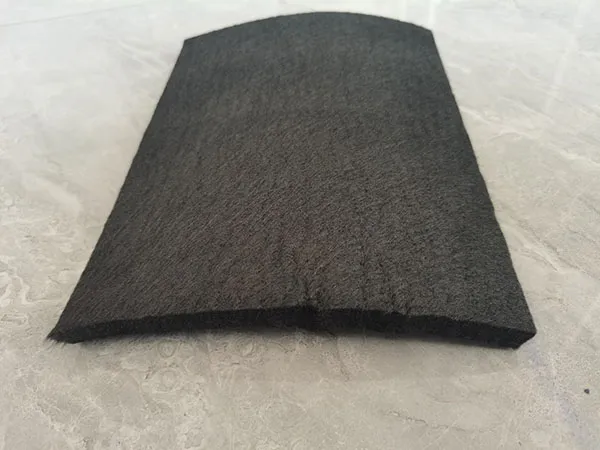

Во время работы, Материалы в HPGR подвергаются интенсивному сжатию и сдвигу между двумя вращающимися роликами. Это постоянное трение и воздействие постепенно развивают ямы, канавки, и трещины на поверхности ролика. Если не адресовано быстро, Ношение ухудшится, влияет на эффективность пульверизации материала и потенциально приводит к вспыльчиванию поверхности ролика и серьезным повреждениям оборудования.

Ремонт поверхности ролика - это больше, чем просто просто “пластырь.” It involves restoring the roller surface’s original dimensions and wear-resistant properties through specialized processes and wear-resistant materials, enabling continued efficient and stable operation.

High-Pressure Grinding Roll Surface Repair Technology Revealed

В настоящее время, the mainstream high-pressure grinding roller (HPGR) roller surface repair technologies on the market are the following:

1. Hardfacing Repair: Precise, Прочный, and Economical

Hardfacing repair is the most widely used and proven roller surface repair method. Using a heat source such as an arc or plasma, specially formulated wear-resistant alloy wire or powder is deposited onto the worn roller surface, forming a new, highly wear-resistant layer.

Technical Advantages:

High Wear Resistance: Using HPGR wear-resistant materials such as high-chromium cast iron and high-carbon, высокоалужная сталь, Отремонтированная поверхность ролика демонстрирует высокую твердость и стойкость к износу, Продолжая срок службы далеко за пределами оригинальной поверхности ролика.

…

Для получения более подробной информации о технологии ремонта поверхности ролика высокого давления, пожалуйста, нажмите здесь: https://www.zymining.com/en/a/news/high-pressure-grinding-rolls-surface-repair-technology.html